Easy-Vortex

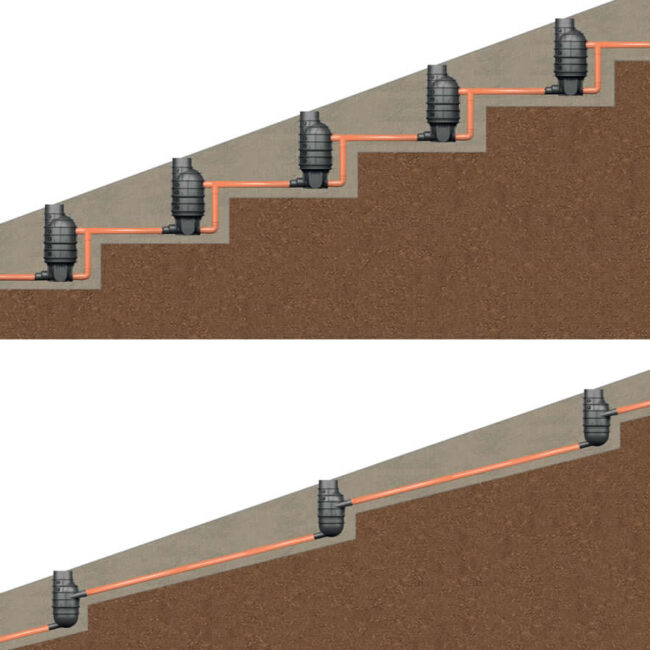

The Easy-Vortex series, developed in diameters 800 and 1000, has been developed to meet the need of dissipating the water energy in the steep incline networks, thus settling the most usual backwater issues, which are typical in the conventional systems.

Application fields

Steep incline pipes

Inspection chamber receiving slurry from a pumping station

For pipes up to OD/DN 630

Inspection chamber type: energy dissipation

Diam. inspection chambers: : 800, 1000

Diam. compatible pipes: : 160, 200, 250, 315, 400, 500, 630

Available dimensions

Polyethylene manholes Easy-Vortex:

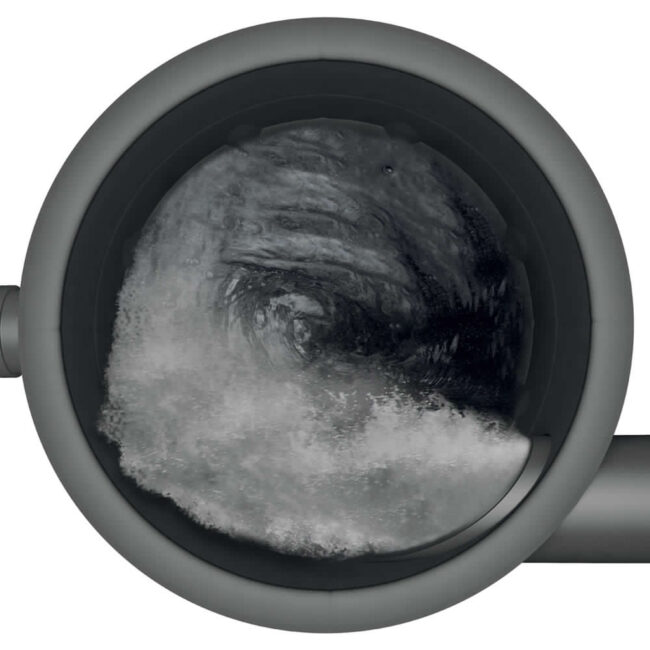

In case of very steep slope, a system dissipating the Energy from the water shall be installed. Thanks to its particular construction with hemispherical bottom, the vortex generated inside the Easy Vortex manhole, dissipates the energy developed by the rise in quota and reduces the maintenance works, making it self-cleaning.

| Code | DN (mm) | Description | Outlet DN (mm) | Nr.Ingr. | Scale | Draw | Specific |

|---|---|---|---|---|---|---|---|

| 080-VR-XXX | 800 | KMC-"Easy Vortex" polyethylene manhole | multi | no | Download | Download |

Who needs to develop a draining scheme of a steep inclined road is always in search of sustainable solutions which could prevent the generation of cavitation areas and therefore the particular aeration phenomena and the subsequent often strong backwater pulses. KMC ran several tests on real physical models and created the EASY-VORTEX DN 1000 manhole, which becomes a mandatory choice to avoid regurgitation phenomena.

| Code | DN (mm) | Description | Outlet DN (mm) | Nr.Ingr. | Scale | Draw | Specific |

|---|---|---|---|---|---|---|---|

| 100-VR-XXX | 1000 | KMC-"Easy Vortex" polyethylene manhole | multi | no | Download | Download |

Advantages versus the conventional systems

IT ELIMINATES THE BACKWATER PHENOMENA

IT ELIMINATES THE BACKWATER PHENOMENA

The Easy-Vortex inspection chamber has been designed to settle the inconveniences linked to the free-fall conditions which are generally used in the design of the steep incline sewers and which originate aeration phenomena and often strong runoff pulses which force the slurry off the inspection chamber covers.

Lower cost

Lower cost

Thanks to its energy dissipation function, Easy-Vortex can reduce the number of inspection chambers required for the development of the network and – furthermore – it is supplied in only one piece with no internal accessories. This means that nothing will ever need to be replaced.

Less manteinance required

Less manteinance required

Thanks to the special conformation of the inspection chamber, and to the hemispherical bottom, besides dissipating the energy due to the change of height, the vortex that generates has a self-cleaning function. The base of the inspection chamber shall always be clear and will not need any cleaning.

LONGER LIFE-SPAN OF THE SEWER NETWORK

LONGER LIFE-SPAN OF THE SEWER NETWORK

Thanks to the low roughness coefficient, to the tangential inlet, to the fast priming of the vortex and to the high coefficient of resistance to abrasion, the life span of the Easy-Vortex inspection chamber is the double than the one of the conventional systems.

SETTLES THE MATTER

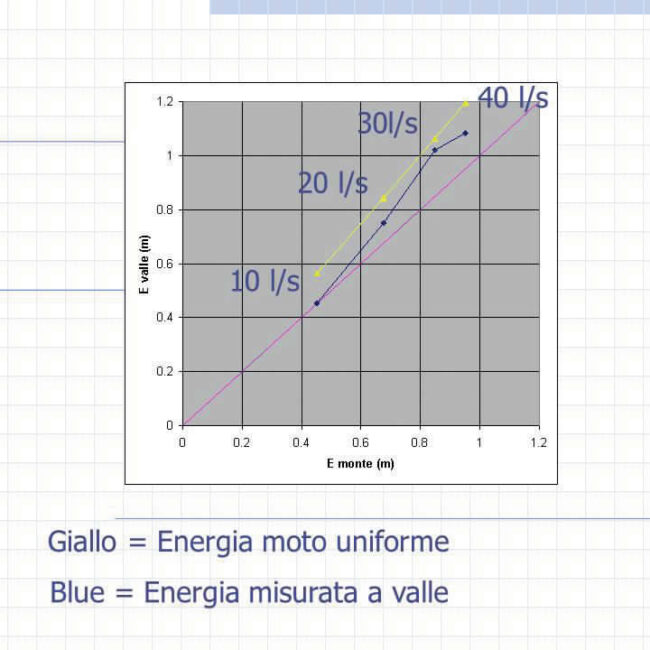

KMC has always been committed in developing products which settle practical matters. Also thanks to the collaboration with important research institutes of both Italian and foreign universities, KMC’s R&D department has set up a sophisticated energy dissipation system called Easy-Vortex, which is based on mathematical models applied to physical systems. The research started from the analysis of other studies which had already been developed in the hydroelectric industry as related to vortex overflows. All such studies had been searching for a model which could prevent the generation of cavitation areas and therefore the particular aeration phenomena and the subsequent often strong backwater pulses, hence the need for an almost complete energy dissipation of the overfill height at the foot of the water well. Even though of different dimensions, the phenomenon that occurs in the sewer is of the same nature. On the basis of the different publications analyzed, we have applied a mathematic model extracted from the Journal of Hydraulic Engrg. ASCE vol. 116 n. 8 1990 “Vortex Drop Inlet for Supercritical Approaching Flow By Willi H. Hager “. Having though realized that the mathematical model adjusted on large-sized overflows could not be applied to the KMC inspection chamber, we immediately ran tests on a real physical model.

The result is the Easy-Vortex system.

REMARK: The Higher Council of Public Works – Central Technical Service, by circular letter of the ministry of public works no. 11633 dated January 7th 1974 established that the following parameters are to be complied with in the design of a draining scheme:

Vmin = 0.5 m/s Vmax <4 m/s waste water

Vmin = 0.5 m/s Vmax <5 m/s rainwater

Why choosing Easy-Vortex?

The Easy-Vortex line developed in diameters 800 – 1000 designed to settle the inconveniences linked to the backwater phenomena of the sloped ducts in conventional systems.

The principles utilized by KCM in standardizing such series have been as follows:

![]() Reduced maintenance and purchasecost.

Reduced maintenance and purchasecost.

![]() Easy quick installation.

Easy quick installation.

![]() Great static resistance to stress.

Great static resistance to stress.

![]() Perfect water-tightness.

Perfect water-tightness.

![]() Compatibility with the networks which are already implemented and reduced of the volume.

Compatibility with the networks which are already implemented and reduced of the volume.

![]() Long life spam.

Long life spam.

Who is the Easy-Vortex series for?

Designers Who show great sense of responsibility towards their clients, with special attention to the technical, economic and environmental aspects.

Providers of public and/or private sewage networks who need to develop a steep incline network and want to avoid the well-known issues of backwater in the ducts, thus settling the matter of those users whose siphons are emptied in case of runoff pulses with the subsequent return of smells of – worse – with the slurry that coming back up the pipes and penetrating the housing facilities.

Providers of public and/or private sewage networks who – having to develop a draining scheme of a steep incline road – intend to eliminate the risks and responsibilities of accidents due to sudden flooding of the roads or unexpected opening of the manhole covers.

All those who intend to adopt and standardize their own networks by a substantially maintenance-free, perfectly watertight inspection chamber, different than the conventional systems, of reduced costs and that cannot be attacked by sulphides and chlorides, that minimizes the cleaning expenses by remarkably reducing the clogging and flooding issues and ensures high valorization, in line with the new concept of eco-sustainable procurement.