Easy Line

A FITTING ON EVERYTHING

The Easy line of the KMC inspection chambers has been developed following the suggestions received from the market in over twenty years of activity. The experience, together with the deep knowledge of the industry, has led us to develop a range of products that allows meeting any type of requirements.

Whether you need low-maintenance siphoned or line “Gully-Pots” (Easy-Gully), small line chambers or connections for private utilization (Easy-Line), large manholes on public ducts (Easy-Inspection), engineered systems such as the energy dissipation in the steep incline lines (Easy-Vortex), or manholes for the containment and inspection of electro-mechanical equipment or wiring (Easy- Utility); the Easy series by KMC offers the ideal solution.

Research and developement.

Since 1996, our company – which is fully made in Italy – has been dealing with the design, production and marketing of polyethylene and polypropylene inspection chambers, as well as of water treatment systems. A core business with the feet on the ground, in which we put all the passion and attention deserved by such a precious resource as water is.

Affidability

Since 1996, our company – which is fully made in Italy – has been dealing with the design, production and marketing of polyethylene and polypropylene inspection chambers, as well as of water treatment systems. A core business with the feet on the ground, in which we put all the passion and attention deserved by such a precious resource as water is.

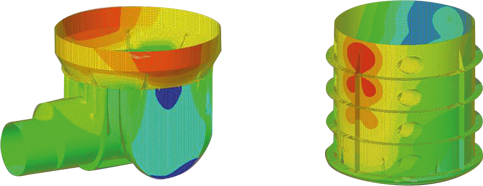

Il pozzetto KMC è stato progettato non solo per rispondere ai requisiti di carico prescritti dalla norma EN 14802:2005, ma per adattarsi alle effettive condizioni di esercizio. Rispetto ai test prescritti infatti il pozzetto KMC considera anche il carico asimmetrico allo scopo di tenere conto di accidentali difetti nel terreno di riempimento o dissimmetrie nell’applicazione dei carichi superficiali. Tali carichi deformano l’elemento già in fase di posa e compattazione e saranno presenti per tutta la vita dello stesso. Qualora si assoggettasse il pozzetto ad un carico radial-simmetrico si otterrebbero solo tensioni lungo la circonferenza e lungo la direzione verticale, poiché tutti i carichi verrebbero assorbiti dalla rigidezza anulare del pozzetto.

L’utilizzo del diagramma delle spinte come in figura provoca una flessione sul piano orizzontale del pozzetto in grado di sviluppare anche momenti flettenti e quindi di tenere conto come accennato di eventuali difetti di compattazione o di eventuali dissimmetrie nell’applicazione dei carichi superficiali.

Ne consegue che il pozzetto KMC è, non solo in teoria, ma anche e soprattutto nella pratica idoneo ad essere installato in condizioni di esercizio reali.

High quality, high fidelity

Our design, production and marketing system is ISO 9001-2008 certified and allows us offering a range of polyethylene inspection chambers consisting of over 300 variants. For us, every order has the same importance and we deal with it with a clear objective: supplying a capable system, which shall be efficient also in extreme conditions, with the same performance and guarantees of the first day.

POLYETHYLENE vs CEMENT