Grease separation plants

GREASE SEPARATION PLANT KMC-LIPORAT®

300 % HIGHER PERFORMANCE THAN CONVENTIONAL ONES

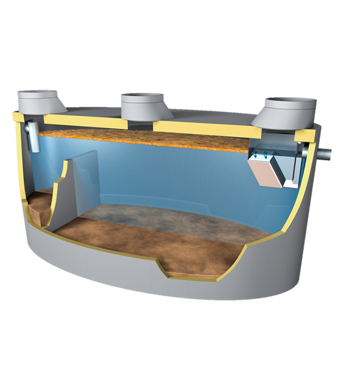

A grease separator is designed to intercept most greases and solids before they enter a wastewater disposal system. KMC has developed together with his Austrian partner a system that guarantees the maintenance of the emission limit values continuously (<100 g/l lipophilic substances). The K.M.C. grease separator can be supplied in one single or two basins. The basins are produced with high quality concrete 50/60 X A2T/XA2L suitable for liquids with pH values from 4,5 up to 8,5.

THE SOLUTION IS KMC-LIPORAT®

Compare to other grease separators on the market, our device have a 300 % higher performance class and a reduction of the pollutant load of ca. 65 %. Maintenance intervals reduced from 2-4 weeks into 6-12 month.

Application fields

The solution for restaurants, butchers, hotels, motorway service areas, or other food-processing industries

Available dimensions

GREASE SEPARATORS IN ACCORDANCE WITH ÖNORM EN1825.

“KMC-KFA” grease separators must be installed wherever there is the possibility of a high grease discharge. Our systems mainly consist of an integrated separator tank, a separator with grease accumulation and a sampling device at the outlet. Type KMC-KFA grease separators are supplied up to a nominal size of 50 in a single tank with integrated bleed. Separators with different configurations can be supplied on special request.

| Code | Pump flow (l/s) | Useful capacity (m³) | External dimensions (cm) | Install. depth (cm) | Inlet depth (cm) | Inlet pipe (mm) | Max weight (ton) | Total weight (ton) | Oil storage (m³) | Drawing | Specifications |

|---|---|---|---|---|---|---|---|---|---|---|---|

| KMC-KFA 2i-EN | 2 | 0.71 | Ø 124 | 195 | 85 | 150 | 1.74 | 2.38 | 0.14 | Download | Download |

| KMC-KFA 4i-EN | 4 | 1.36 | Ø 144 | 225 | 85 | 150 | 2.53 | 3.36 | 0.2 | Download | Download |

| KMC-KFA 5i-EN | 5 | 1.37 | Ø 174 | 208 | 83 | 150 | 2.89 | 4.06 | 0.32 | Download | Download |

| KMC-KFA 7i-EN | 7 | 2.06 | Ø 174 | 260 | 85 | 150 | 3.66 | 4.83 | 0.32 | Download | Download |

| KMC-KFA 12i-EN | 12 | 4.74 | Ø 224 | 258 | 88 | 200 | 5.07 | 7.04 | 1.25 | Download | Download |

| KMC-KFA 15i-EN | 15 | 5.12 | Ø 274 | 210 | 90 | 200 | 5.36 | 8.23 | 0.6 | Download | Download |

| KMC-KFA 19i-EN | 19 | 4.74 | Ø 274 | 260 | 90 | 200 | 6.58 | 9.45 | 0.88 | Download | Download |

The KMC-LIPORAT® is a system that ensures that emission limit values (<100 mg/l lipofile substances) are continuously and sustainably maintained. The KMC-LIPORAT® system can be supplied as a monobloc or as a two-tank version. The compact version consists of a coarse substance separator and a remnant grease separator with integrated bleed. The LIPORAT® system can also be used in the two-tank version to recover existing installations and thus bring the drains up to standard economically. The tanks are made of the highest quality cement C50/60 XA2T/XA2L, and are therefore suitable for containing sewage with pH values between 4.5 and 8.5.

| Code | Pump flow (l/s) | Useful capacity (m³) | External dimensions (cm) | Install. depth (cm) | Inlet depth (cm) | Inlet pipe (mm) | Max weight (ton) | Total weight (ton) | Oil storage (m³) | Drawing | Specifications |

|---|---|---|---|---|---|---|---|---|---|---|---|

| KMC/LIP-2i-EN | 2 | 5 | Ø 224 | 258 | 83 | 150 | 5.85 | 7.8 | 1.257 | Download | Download |

| KMC/LIP-4i-EN | 4 | 7.8 | Ø 274 | 260 | 85 | 150 | 7.47 | 10.34 | 1.257 | Download | Download |

| KMC/LIP-6i-EN | 6 | 11.17 | 430x250 | 260 | 90 | 200 | 10.49 | 15.32 | 2.22 | Download | Download |

| KMC/LIP-8i-EN | 8 | 16.35 | 430x250 | 328 | 88 | 200 | 12.34 | 16.44 | 2.22 | Download | Download |

| KMC/LIP-12i-EN | 12 | 26.53 | 594x297 | 332 | 92 | 200 | 20.14 | 27.97 | 4.868 | Download | Download |

Advantages over traditional systems

Extended maintenance intervals: from 2 – 4 weeks to 6 – 12 months

Reduction of pollutant load by approx. 65 %

Why choose Fat Separators?

While conventional grease separators achieve emission values of 300-600 mg/l at most, the KMC-LIPORAT system achieves values of < 73 mg/l on average.

Who is the Fat Separators line aimed at?

Hotels, Restaurants, Canteens.