Oil separation plants

The oil separator is a plant designed to separate gasoline, oils, greases and other light parts of petroleum products.

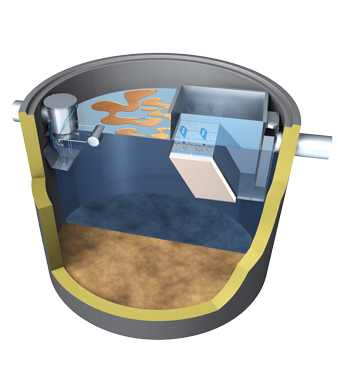

Basically there are two different kind of oil separators: the gravity or conventional separator and the coalescent filter separator, a type of plant, which the KMC-SMA separator belongs to and which improves the oils separation efficiency, thanks to a lamellar pack, which, increasing the effective flotation area, eases the aggregation of the lightest particles and their ascending.

This process allows a reduction of the plant dimensions, much smaller than the bigger gravity oil separators.

The oil separation is achieved by reducing the speed of the influent and by providing a setting area in which the present substances, characterized by a specific weight, lower than the water’s, ascend by floating. The operation of the oil separators can be referred to the principles of sedimentation under the action of the gravity. These act in fact as sedimentation basins, in which the oil particles instead of settling on the bottom, float on the surface.

Advantages versus the conventional systems

– Reduced maintenance costs and simple in maintenance. Thanks to the generous volumes of accumulation, frequency of removal of sludge/oil is highly reduced.

– No consumption of electricity.

– Emission limit values below the legal limit values (D.lgs. 152/99 – All.5, tab.3 – val.37)

– Testing in accordance with EN 858-1/2, registration of testing in accordance with ÖNORM B 5101

– Inspection by third parties according to ÖNORM B 5101.

– Production certificated by DIN EN ISO 9001 (design and production)

Why choosing Oil separation plants?

The coalescing plate pack system guarantees much better performances compared to standard sponge filters.

– More than 20 year experience and know-how in the field of oil separation

– Sludge section and gravity separator with large accumulation capacity in order to reduce frequency of maintenance.

– Sampling can be done directly on the outlet of the separator

– Oil separator with technology of coalescing plate pack which guarantees highest level of separation and reduction of maintenance costs.

– Precast monolithic tank made with reinforced concrete (min. C45/55 X A2T)

Who is the Oil separation plants series for?

For anyone who handles mineral oil or light liquids.

Application fields

Everywhere they are handled mineral oil or light-liquids, an oil separator system has to be installed.

The UNI 858 point. 4.1. lays down, dividing in 3 categories and giving to each of them a minimum impediment factor (fx), where an oil separator has to be installed:

Cat.A) for treatment of industrial waste water from car-washing, cleaning of oil covered parts and items for example petrol stations; impediment factor (fx=2)

Cat.B) for treatment of oil-contaminated rainwater (superficial water flow) from areas which access is difficult for example parking facilities, roads, etc. (fx=0)

Cat.C) for containment of accidental overthrow of light-liquids and protection of the surrounding area (fx=1)

CRITERION OF DIMENSIONING OIL SEPARATORS ACCORDING TO EN 858-1

In case no specific criterion of dimensioning from the authority is given, the nominal dimensions of the oil separator has to be determined, taking into account the following:

Maximum flow of rainwater; (Qr)

Maximum flow of waste water (commercial effluents; (Qs)

Volume mass of the light liquid; (fd)

Presence of substances which may avoid the separation (detergent solutions); (Qr)

Features

All KMC oil separators are made of concrete of the highest quality (minimum C45/55 X A2T).

At the entry of the oil separator a patented self-closing device is installed, which prevents any spillage of mineral oils.

The filter pack provided with advanced module lamellar plates ensures the separation of the finest oil particles and a very high and constant separation performance. The big volumes designed for the sludge and oil accumulation and the technology of the filtering pack provided with lamellar plates, allow longer maintenance intervals and a higher performance level, compared to the conventional gravity oil separation plants. The KMC oil separator can be provided with stainless steel or PEAD equipment.

What never may enter the oil separator:

The oil separator may enter only waste water containing oils which can be separated. In order to obtain highest separation levels it’s very important to use only cleaning agents according to OENORM B 5102, B 5105 and B 5106. All other cleaning agents may cause emulsions which cannot be separated with an standard oil separator. .

What never may enter the oil separator:

Civil waste water

Flow rates greater than the capacity of the oil separator

Substances limiting the operation of the separator, such as battery acid, brake fluid, antifreeze,…)

Underbody cleaning water

Stable emulsions coming from carwash

Sludge and concentrates from water recycling plants or other waste water plants

Wastewater originating from other oil separators or sludge tanks.

Available dimensions

Water treatment Oil separation plants KMC-SMA

All ‘KMC/SMA’ type oil separators are made of the highest quality cement (minimum C45/55 X A2T). A patented automatic closure is located at the inlet of the oil separator, which prevents mineral oil from escaping.

The advanced lamellar plate filtering package guarantees the separation of the finest oil particles and thus a consistently high degree of separation. The generously designed sludge and oil storage volumes and the technology of the flap plate oil separator package allow longer maintenance intervals and a much higher yield than with conventional oil separators. The KMC/SMA type oil separator can be supplied with stainless steel or PEAD internal equipment.

| Code | Pump flow (l/s) | Useful capacity (m³) | External dimensions (cm) | Install. depth (cm) | Inlet depth (cm) | Inlet pipe (mm) | Max weight (ton) | Total weight (ton) | Oil storage (m³) | Drawing | Specifications |

|---|---|---|---|---|---|---|---|---|---|---|---|

| KMC/SMA 2/4-0,9-EN | 3 | 0.9 | Ø 174 | 208 | 83 | 160 | 2.96 | 4.45 | 0.35 | Download | Download |

| KMC/SMA 2/4-0,9-EN-K | 3 | 0.9 | Ø 174 | 210 | 85 | 160 | 2.96 | 4.08 | 0.35 | Download | Download |

| KMC/SMA 2/4-1,4-EN | 3 | 1.4 | Ø 174 | 238 | 83 | 160 | 3.43 | 4.92 | 0.35 | Download | Download |

| KMC/SMA 2/4-1,4-EN-K | 3 | 1.4 | Ø 174 | 240 | 85 | 160 | 3.43 | 4.55 | 0.35 | Download | Download |

| KMC/SMA 2/4-1,8-EN | 3 | 1.8 | Ø 174 | 258 | 83 | 160 | 3.73 | 5.21 | 0.35 | Download | Download |

| KMC/SMA 2/4-1,8-EN-K | 3 | 1.8 | Ø 174 | 260 | 85 | 160 | 3.73 | 4.85 | 0.35 | Download | Download |

| KMC/SMA 2/4-2,5-EN | 3 | 2.5 | Ø 224 | 238 | 83 | 160 | 4.71 | 7 | 0.68 | Download | Download |

| KMC/SMA 2/4-2,5-EN-K | 3 | 2.5 | Ø 224 | 250 | 95 | 160 | 4.71 | 6.4 | 0.68 | Download | Download |

| KMC/SMA 2/4-2,6-EN | 3 | 2.6 | Ø 174 | 308 | 83 | 160 | 4.25 | 6.01 | 0.35 | Download | Download |

| KMC/SMA 2/4-2,6-EN-K | 3 | 2.6 | Ø 174 | 308 | 83 | 160 | 4.25 | 6.01 | 0.35 | Download | Download |

| KMC/SMA 2/4-3,2-EN | 3 | 3.2 | Ø 224 | 258 | 83 | 160 | 5.12 | 7.41 | 0.68 | Download | Download |

| KMC/SMA 2/4-3,2-EN-K | 3 | 3.2 | Ø 224 | 270 | 95 | 160 | 5.12 | 6.81 | 0.68 | Download | Download |

| KMC/SMA 2/4-5,0-EN | 3 | 5 | Ø 224 | 308 | 83 | 160 | 6.14 | 8.43 | 0.68 | Download | Download |

| KMC/SMA 2/4-5,0-EN-K | 3 | 5 | Ø 224 | 320 | 95 | 160 | 6.14 | 7.83 | 0.68 | Download | Download |

| KMC/SMA 2/4-5,1-EN | 3 | 5.1 | Ø 274 | 258 | 83 | 160 | 6.87 | 10.02 | 1.1 | Download | Download |

| KMC/SMA 2/4-7,4-EN | 3 | 7.4 | Ø 274 | 308 | 83 | 160 | 7.6 | 10.75 | 1.1 | Download | Download |

| KMC/SMA 2/4-9,8-EN | 3 | 9.8 | Ø 274 | 358 | 83 | 160 | 8.08 | 11.23 | 1.1 | Download | Download |

| KMC/SMA 6/8-1,4-EN | 6 | 1.4 | Ø 174 | 238 | 83 | 160 | 3.45 | 4.94 | 0.32 | Download | Download |

| KMC/SMA 6/8-1,4-EN-K | 6 | 1.4 | Ø 174 | 240 | 85 | 160 | 3.45 | 4.57 | 0.32 | Download | Download |

| KMC/SMA 6/8-1,8-EN | 6 | 1.8 | Ø 174 | 258 | 83 | 160 | 3.75 | 5.24 | 0.32 | Download | Download |

| KMC/SMA 6/8-1,8-EN-K | 6 | 1.8 | Ø 174 | 260 | 85 | 160 | 3.75 | 4.87 | 0.32 | Download | Download |

| KMC/SMA 6/8-2,5-EN | 6 | 2.5 | Ø 225 | 238 | 83 | 160 | 4.73 | 7.02 | 0.65 | Download | Download |

| KMC/SMA 6/8-2,5-EN-K | 6 | 2.5 | Ø 225 | 250 | 95 | 160 | 4.73 | 6.42 | 0.65 | Download | Download |

| KMC/SMA 6/8-3,2-EN | 6 | 3.2 | Ø 224 | 258 | 83 | 160 | 5.14 | 7.43 | 0.65 | Download | Download |

| KMC/SMA 6/8-3,2-EN-K | 6 | 3.2 | Ø 224 | 270 | 95 | 160 | 5.14 | 6.83 | 0.65 | Download | Download |

| KMC/SMA 6/8-5,0-EN | 6 | 5 | Ø 224 | 308 | 83 | 160 | 6.16 | 8.45 | 0.65 | Download | Download |

| KMC/SMA 6/8-5,0-EN-K | 6 | 5 | Ø 224 | 320 | 95 | 160 | 6.16 | 7.85 | 0.65 | Download | Download |

| KMC/SMA 6/8-5,1-EN | 6 | 5.1 | Ø 274 | 258 | 83 | 160 | 6.89 | 10.04 | 1.07 | Download | Download |

| KMC/SMA 6/8-7,4-EN | 6 | 7.4 | Ø 224 | 308 | 83 | 160 | 7.62 | 10.77 | 1.07 | Download | Download |

| KMC/SMA 6/8-9,8-EN | 6 | 9.8 | Ø 270 | 358 | 83 | 160 | 8.1 | 11.25 | 1.07 | Download | Download |

| KMC/SMA 10/12-1,0-EN | 10 | 1 | Ø 174 | 208 | 88 | 200 | 3.03 | 4.31 | 0.21 | Download | Download |

| KMC/SMA 10/12-1,4-EN | 10 | 1.4 | Ø 174 | 238 | 88 | 200 | 3.51 | 5 | 0.21 | Download | Download |

| KMC/SMA 10/12-1,8-EN | 10 | 1.8 | Ø 174 | 288 | 88 | 200 | 3.81 | 5.3 | 0.21 | Download | Download |

| KMC/SMA 10/12-1,8-EN-K | 10 | 1.8 | Ø 174 | 290 | 90 | 200 | 3.8 | 4.82 | 0.21 | Download | Download |

| KMC/SMA 10/12-2,1-EN | 10 | 2.1 | Ø 174 | 308 | 88 | 200 | 4.13 | 5.62 | 0.21 | Download | Download |

| KMC/SMA 10/12-2,5-EN | 10 | 2.5 | Ø 224 | 238 | 88 | 200 | 4.79 | 7.08 | 0.54 | Download | Download |

| KMC/SMA 10/12-2,5-EN-K | 10 | 2.5 | Ø 224 | 250 | 100 | 200 | 4.79 | 6.48 | 0.54 | Download | Download |

| KMC/SMA 10/12-3,2-EN | 10 | 3.2 | Ø 224 | 258 | 88 | 200 | 5.4 | 7.49 | 0.54 | Download | Download |

| KMC/SMA 10/12-3,2-EN-K | 10 | 3.2 | Ø 224 | 270 | 100 | 200 | 5.2 | 6.89 | 0.54 | Download | Download |

| KMC/SMA 10/12-3,8-EN | 10 | 3.8 | Ø 224 | 278 | 88 | 200 | 5.61 | 7.9 | 0.54 | Download | Download |

| KMC/SMA 10/12-5,0-EN | 10 | 5 | Ø 224 | 308 | 88 | 200 | 6.22 | 8.51 | 0.54 | Download | Download |

| KMC/SMA 10/12-5,0-EN-K | 10 | 5 | Ø 224 | 318 | 100 | 200 | 6.22 | 7.91 | 0.54 | Download | Download |

| KMC/SMA 10/12-5,1-EN | 10 | 5.1 | Ø 274 | 260 | 90 | 200 | 6.95 | 10.1 | 0.98 | Download | Download |

| KMC/SMA 14/16-1,0-EN | 15 | 1 | Ø 174 | 210 | 90 | 200 | 3.04 | 4.53 | 0.21 | Download | Download |

| KMC/SMA 14/16-1,0-EN-K | 15 | 1 | Ø 174 | 210 | 90 | 200 | 3.03 | 4.16 | 0.21 | Download | Download |

| KMC/SMA 14/16-2,5-EN | 15 | 2.5 | Ø 224 | 238 | 88 | 200 | 4.79 | 7.08 | 0.54 | Download | Download |

| KMC/SMA 14/16-3,2-EN | 15 | 3.2 | Ø 224 | 258 | 88 | 200 | 5.2 | 7.49 | 0.54 | Download | Download |

| KMC/SMA 14/16-3,2-EN-K | 15 | 3.2 | Ø 224 | 270 | 95 | 200 | 5.2 | 6.89 | 0.54 | Download | Download |

| KMC/SMA 14/16-3,8-EN | 15 | 3.8 | Ø 224 | 278 | 88 | 200 | 5.61 | 7.9 | 0.54 | Download | Download |

| KMC/SMA 14/16-5,0-EN | 15 | 5 | Ø 224 | 308 | 88 | 200 | 6.22 | 8.51 | 0.54 | Download | Download |

| KMC/SMA 14/16-5,1-EN | 15 | 5.1 | Ø 274 | 260 | 90 | 200 | 6.95 | 10.1 | 0.98 | Download | Download |

| KMC/SMA 14/16-10,5-EN | 15 | 10.5 | 430×250 | 228 | 100 | 200 | 11.79 | 15.89 | 0.54 | Download | Download |

| KMC/SMA 20-1,6-EN | 20 | 1.6 | Ø 224 | 208 | 88 | 200 | 4.18 | 6.47 | 0.68 | Download | Download |

| KMC/SMA 20-1,6-EN-K | 20 | 1.6 | Ø 224 | 220 | 100 | 200 | 4.18 | 6.47 | 0.68 | Download | Download |

| KMC/SMA 20-2,5-EN | 20 | 2.5 | Ø 224 | 238 | 88 | 200 | 4.79 | 7.08 | 0.54 | Download | Download |

| KMC/SMA 20-2,5-EN-K | 20 | 2.5 | Ø 224 | 252 | 102 | 200 | 4.78 | 6.25 | 0.54 | Download | Download |

| KMC/SMA 20-3,2-EN | 20 | 3.2 | Ø 224 | 258 | 88 | 200 | 7.49 | 7.49 | 0.54 | Download | Download |

| KMC/SMA 20-3,2-EN-K | 20 | 3.2 | Ø 224 | 270 | 100 | 200 | 5.2 | 6.89 | 0.54 | Download | Download |

| KMC/SMA 20-5,0-EN | 20 | 5 | Ø 224 | 308 | 88 | 200 | 6.22 | 8.51 | 0.54 | Download | Download |

| KMC/SMA 20-5,0-EN-K | 20 | 5 | Ø 224 | 320 | 100 | 200 | 6.22 | 8.14 | 0.54 | Download | Download |

| KMC/SMA 20-5,1-EN | 20 | 5.1 | Ø 274 | 260 | 90 | 200 | 6.95 | 10.1 | 0.98 | Download | Download |

| KMC/SMA 20-7,0-EN | 20 | 7 | 430×250 | 258 | 88 | 200 | 9.46 | 13.56 | 1.59 | Download | Download |

| KMC/SMA 30-0,8-EN | 30 | 0.8 | Ø 224 | 208 | 98 | 315 | 4.27 | 6.56 | 0.68 | Download | Download |

| KMC/SMA 30-1,7-EN | 30 | 1.7 | Ø 224 | 238 | 98 | 315 | 4.88 | 7.17 | 0.68 | Download | Download |

| KMC/SMA 30-2,4-EN | 30 | 2.4 | Ø 224 | 258 | 98 | 315 | 5.29 | 7.58 | 0.68 | Download | Download |

| KMC/SMA 30-3,7-EN | 30 | 3.7 | Ø 274 | 258 | 98 | 315 | 7.04 | 10.19 | 1.3 | Download | Download |

| KMC/SMA 30-4,0-EN | 30 | 4 | Ø 224 | 308 | 98 | 315 | 6.31 | 8.6 | 0.68 | Download | Download |

| KMC/SMA 30-5,2-EN | 30 | 5.2 | 430×250 | 258 | 98 | 315 | 9.52 | 13.62 | 2.17 | Download | Download |

| KMC/SMA 30-6,2-EN | 30 | 6.2 | Ø 274 | 308 | 98 | 315 | 7.77 | 10.92 | 1.3 | Download | Download |

| KMC/SMA 30-8,6-EN | 30 | 8.6 | Ø 270 | 358 | 98 | 315 | 8.25 | 11.4 | 1.3 | Download | Download |

| KMC/SMA 30-10,5-EN | 30 | 10.5 | 430×250 | 328 | 98 | 315 | 11.74 | 15.84 | 2.17 | Download | Download |

| KMC/SMA 40-3,7-EN | 40 | 3.7 | Ø 274 | 258 | 98 | 315 | 7.11 | 10.26 | 1.09 | Download | Download |

| KMC/SMA 40-5,2-EN | 40 | 5.2 | 430×250 | 258 | 98 | 315 | 9.53 | 13.63 | 1.96 | Download | Download |

| KMC/SMA 40-6,2-EN | 40 | 6.2 | Ø 274 | 308 | 98 | 315 | 8.06 | 11.01 | 1.09 | Download | Download |

| KMC/SMA 40-8,6-EN | 40 | 8.6 | Ø 270 | 358 | 98 | 315 | 8.32 | 11.47 | 1.09 | Download | Download |

| KMC/SMA 40-10,5-EN | 40 | 10.5 | 430×250 | 328 | 98 | 315 | 11.76 | 15.86 | 1.96 | Download | Download |

| KMC/SMA 40-21,0 | 40 | 40 | 700×250 | 338 | 98 | 315 | 21.13 | 29.3 | 3.78 | Download | Download |

| KMC/SMA 50-1,3-EN | 50 | 1.3 | Ø 274 | 208 | 98 | 315 | 5.76 | 8.91 | 1.09 | Download | Download |

| KMC/SMA 50-3,7-EN | 50 | 3.7 | Ø 274 | 258 | 98 | 315 | 7.11 | 10.26 | 1.09 | Download | Download |

| KMC/SMA 50-5,2-EN | 50 | 5.2 | 430×250 | 258 | 98 | 315 | 9.62 | 13.82 | 1.96 | Download | Download |

| KMC/SMA 50-6,2-EN | 50 | 6.2 | Ø 274 | 308 | 98 | 315 | 7.84 | 10.99 | 1.09 | Download | Download |

| KMC/SMA 50-8,6-EN | 50 | 8.6 | Ø 270 | 358 | 98 | 315 | 8.32 | 11.47 | 1.09 | Download | Download |

| KMC/SMA 50-10,5-EN | 50 | 10.6 | 430×250 | 328 | 98 | 315 | 11.79 | 15.89 | 1.96 | Download | Download |

| KMC/SMA 65-2,3-EN | 65 | 2.3 | 430×250 | 288 | 128 | 315 | 10.95 | 15.26 | 2.22 | Download | Download |

| KMC/SMA 65-2,3-EN-2K | 65 | 2.3 | 594×295 | 290 | 130 | 315 | 10.99 | 15.3 | 2.22 | Download | Download |

| KMC/SMA 65-7,4-EN | 65 | 7.4 | 430×250 | 358 | 128 | 315 | 13.76 | 18.07 | 2.22 | Download | Download |

| KMC/SMA 65-7,4-EN-2K | 65 | 7.4 | 430×250 | 360 | 130 | 315 | 13.76 | 18.07 | 2.22 | Download | Download |

| KMC/SMA 65-9,6-EN | 65 | 9.6 | 430×250 | 358 | 98 | 315 | 14.95 | 19.26 | 2.22 | Download | Download |

| KMC/SMA 80-2,3-EN | 80 | 2.3 | 430×250 | 258 | 108 | 400 | 11.02 | 15.33 | 2.22 | Download | Download |

| KMC/SMA 80-2,3-EN-2K | 80 | 2.3 | 430×250 | 290 | 140 | 400 | 11.02 | 15.33 | 2.22 | Download | Download |

| KMC/SMA 80-7,4-EN | 80 | 7.4 | 430×250 | 328 | 108 | 400 | 13.83 | 18.14 | 2.22 | Download | Download |

| KMC/SMA 80-9,6-EN | 80 | 9.6 | 430×250 | 358 | 110 | 400 | 15.02 | 19.33 | 2.22 | Download | Download |

| KMC/SMA 100-2,3-EN | 100 | 2.3 | 430×250 | 258 | 108 | 400 | 10.99 | 15.3 | 2.22 | Download | Download |

| KMC/SMA 100-7,4-EN | 100 | 7.4 | 430×250 | 358 | 108 | 400 | 13.8 | 18.11 | 2.22 | Download | Download |

| KMC/SMA 100-10,0-EN | 100 | 10 | 430×250 | 358 | 108 | 400 | 14.99 | 19.3 | 2.22 | Download | Download |

| KMC/SMA 125-15,8-EN | 125 | 15.81 | 600X250 | 338 | 108 | 400 | 20.53 | 27.86 | 3.47 | Download | Download |

| KMC/SMA 150-15,8-EN | 150 | 15.8 | 600X250 | 338 | 108 | 400 | 21.16 | 28.8 | 1.92 | Download | Download |

| KMC/SMA 175-19,1-EN | 175 | 19.1 | 700X250 | 338 | 108 | 400 | 24.02 | 32.92 | 2.48 | Download | Download |

| KMC/SMA 200-22,8-EN | 200 | 22.8 | 800X250 | 338 | 118 | 500 | 26.93 | 36.82 | 3.04 | Download | Download |